Call Us :

08045802772

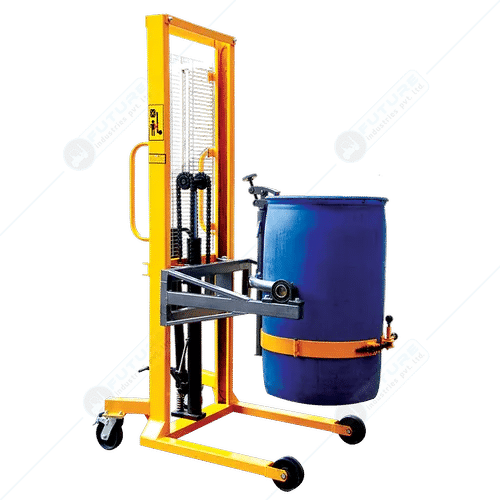

Drum Lifter Trolley

Product Details:

- Condition New

- Max. Lifting Height 1000-1250 mm,1600 /3000 mm Millimeter (mm)

- Warranty Yes

- Click to view more

Drum Lifter Trolley Price

- 4100.00 - 15000.00 INR/Piece

- 1 Unit

- 120000 INR/Piece

Drum Lifter Trolley Specification

- Yes

- 1000-1250 mm,1600 /3000 mm Millimeter (mm)

- New

Drum Lifter Trolley Information

- Telegraphic Transfer (T/T) Cheque

- 500 Unit Per Month

- 1 Week

- Australia North America South America Eastern Europe Western Europe Middle East Central America Africa Asia

- All India

Product Description

Backed by a deft team of technical experts, we are able to manufacture, export and supply a wide assortment of Drum Lifter Trolley. This lifter is precisely manufactured with the help of ultra-modern technology using the finest quality raw material in adherence with predefined industry norms. Offered mechanical equipment is widely used to handle and transport cylindrical modules. Moreover, we provide this Drum Lifter Trolley in diverse specifications and at affordable rates

The Drum Lifter Trolley is the ideal tool for handling drums securely and effectively. This sturdy and well-designed trolley is made to simplify the transportation of drums for your industrial activities. It can easily take the weight of normal drums because of its strong construction and ergonomic features, providing easy movement to your workstation. Our Drum Lifter Trolley prioritizes the safety of your personnel while securing your priceless commodities thanks to its easy-to-use controls and security features. With our superior trolley, you can increase output, reduce labor requirements, and improve workplace safety right now. a

Drum Lifter Trolley Features:

- Auto finish coating to avoid corrosion

- PTFE seals ensure long life smooth working

- Picks drum vertically from floor

- Rollers allows easy faucet positioning of drums

- Simple structure made from heavy duty

- Steel, Fiber and Plastic Drum Lifter

Drum Lifter Trolley Specifications:

- Capacity : 210 liter or 500 kgs

- Tilting angle : 0 degree to 360 degree

- 8 x 2 inch nylon swivel castor wheel

- 100 x 40 nylon roller wheel

- Paint : auto-finish paint.

- Hydraulic electric power pack unit (optional)

- Height safety control : limit switch for height safety control.

- Cable : 3 meter standard length cable

More Details of Drum Lifter Trolley:

- Drum holder : by means of pipe with positive gripping and fabricated belt

- Drum tilting : high quality solid steel used to construct drum lifter cum tilter that provides stability during transit. The angle and height of drum pouring can be controlled at the time of dispensing. A hand gear can be used to rotate the drum 360 deg.

- Structure : heavy duty C channel section is used to make simplex single mast structure. The support of heavy-duty deep grooved guide rollers helps in achieving it smoothly. 2 nos. Duplex chain & design pulley are used for Forks lifting.

- Hydraulic unit : single acting cylinder piston rod is used to support the part of hydraulic cylinder is inducted with hard chrome plated. The sealing arrangement is of PTFE seals and polyurethane seals for smooth working and long life. Viper seals which are leak proof will be given to protect from ingress & dust dirt

- Hydraulic pump part : lifting of the cylinder would be with the help of single acting hand pump

- Handle : designed for best maneuver ability & made of m. S. Pipe

- Paint : Auto-finish paint.

Drum Lifter Trolley Benefits:

- The Drum Lifter Trolley makes handling drums easier while streamlining workflow and reducing wasted time when performing transportation activities.

- The trolley prioritizes the safety of its users and the surrounding workforce by reducing the possibility of accidents and injuries.

- This trolley has a strong construction that can easily handle heavy weights and was designed to survive harsh industrial conditions.

- Its intuitive design makes it simple to move around obstacles and across confined areas, delivering optimum flexibility and agility in any environment.

- The Drum Lifter Trolley is flexible equipment appropriate for numerous industries and applications since it can accept different drum sizes and kinds.

- Drum handling is made more pleasant and effective throughout the workday thanks to ergonomically engineered controls and features that lessen operator fatigue and strain.

Drum Lifter Trolley FAQ:

Is the trolley easy to maneuver in tight spaces?

Absolutely! The trolley is designed with excellent maneuverability, making it easy to navigate even in tight spaces.

Is the trolley suitable for indoor and outdoor use?

Yes, the trolley is perfectly suitable for both indoor and outdoor use, providing versatile performance in various environments.

Can the trolley handle uneven surfaces?

Certainly! The trolley is designed to handle uneven surfaces with ease, ensuring smooth transportation of drums across various terrains.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free