Call Us :

08045802772

Loading Dock Levelers

Product Details:

- Motor Type Three-phase induction motor

- Wheel Type Stationary Plates

- Control System Push Button control panel

- Lifting Speed Adjustable

- Forklift Compatible

- Features Anti-slip surface, Easy Installation

- Equipment Type Loading Dock Levelers

- Click to view more

Loading Dock Levelers Price

- 1 Piece

- 175000 INR/Piece

- 150000.00 - 150000.00 INR/Piece

Loading Dock Levelers Specification

- 2-3 kW

- up to 700 mm

- Push Button control panel

- Stationary Plates

- Loading Dock Levelers

- as par requirment Metric Ton

- New

- 380 V

- Three-phase induction motor

- Electric

- Anti-slip surface, Easy Installation

- Hydraulic Operation

- as par requirment

- Compatible

- Heavy Duty Construction

- Adjustable

Loading Dock Levelers Trade Information

- 1 Piece Per Day

- 3-4 Days

Product Description

This advanced leveler has been designed to make sure the movement from your plants loading dock to the transport vehicle is both safe and easy. Meticulously crafted to match the demands of modern logistics, our Loading Dock Leveler boasts a robust build that blends strong materials with expert engineering. This ensures it can effortlessly handle heavy loads while maintaining its durability.

Loading Dock LevelersBenefits:

- Allows seamless transfer of goods between trucks and docks.

- Reduces the risk of accidents during loading and unloading.

- Minimizes strain on workers, promoting better safety.

- Increases loading/unloading efficiency and saves time

Loading Dock Leveler Technical Specification:

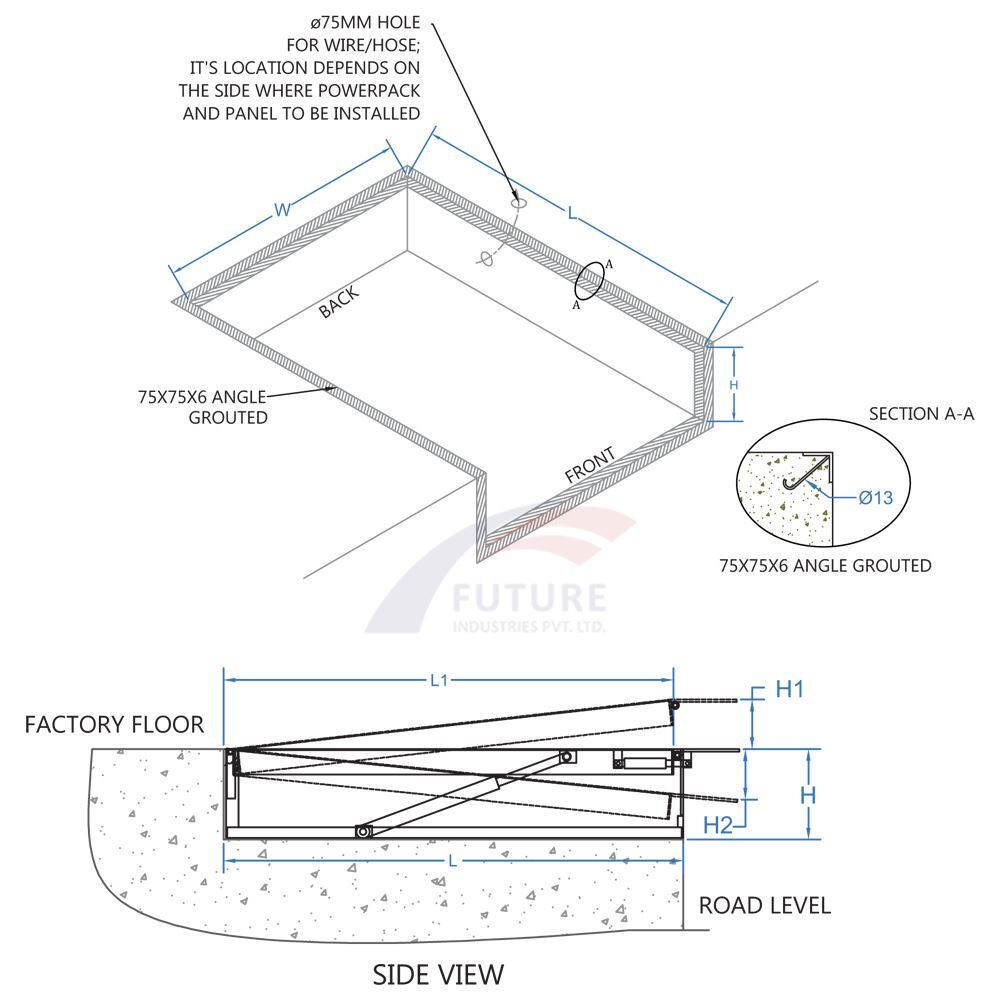

- Capacity: 6000 kg

- Model Name/Number: FIE-191

- Equipment Type: Dock Leveler

- Function Type: Electro / Hydraulic

- Deck Length: 2640 mm

- Working Range: Frame Height

- Power Supply: 50Hz-415v

- Overall Length with Lip Extended: 3050 mm

- Lip Extension: 410 mm

- Frame Height: 610 mm

- Deck Width: 2030 mm

Loading Dock LevelersFAQs:

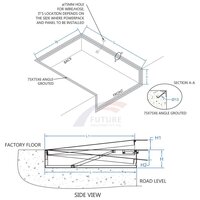

What is the role of a dock leveler pit in the installation process?

The dock leveler pit provides a recessed space for the leveler to sit flush with the dock floor, allowing smooth loading and unloading of trucks.

How do I ensure compatibility between loading dock levelers and various trucks?

To ensure compatibility, consider the range of truck heights and weights youll encounter, and choose a loading dock leveler with adjustable features that accommodate these variations.

Robust and Reliable Design

These Loading Dock Levelers are crafted with high-strength steel and an industrial-grade epoxy powder coating, ensuring resistance to wear and corrosion. The heavy-duty construction is built to withstand continuous use in busy warehouse, logistics, and distribution settings, delivering long-term reliability.

Advanced Safety Features

Operator safety is paramount, with integrated side safety toes to prevent foot injuries during operation and an emergency stop switch for instant shutdown if necessary. Reinforced lip and anti-slip surface features further minimize risk, making daily operations safer and more efficient.

Effortless Hydraulic Operation

The hydraulic system, driven by a three-phase induction motor and controlled via a user-friendly push button panel, provides smooth and adjustable lifting. The leveler supports continuous duty cycles, and its adaptable lifting speed allows precise positioning for efficient loading and unloading.

FAQs of Loading Dock Levelers:

Q: How are these loading dock levelers installed in various facilities?

A: These dock levelers can be installed as either pit-mounted or surface-mounted units, making them suitable for both new facilities and retrofitting existing ones. The design ensures easy installation with minimal downtime.Q: What safety measures are built into these loading dock levelers?

A: The levelers feature side safety toes to protect operators from accidental foot injuries and an emergency stop switch for immediate halting of operation. The anti-slip surface further enhances workplace safety during use.Q: When is it recommended to use high-strength steel dock levelers?

A: High-strength steel dock levelers are ideal for heavy-duty applications in warehouses, logistics centers, and distribution hubs where equipment is subject to demanding, continuous use and exposure to varying temperatures ranging from -10C to +50C.Q: What are the operational benefits of hydraulic operation with a push button control panel?

A: Hydraulic operation ensures smooth and consistent lifting, while the push button control panel allows operators to easily adjust lifting speeds and positions, enhancing efficiency and reducing manual labor.Q: Where is the best application environment for these dock levelers?

A: These levelers are designed for industrial settings such as warehouses, logistics centers, and distribution hubs, where heavy loads, frequent equipment movement, and efficiency are crucial.Q: What is the process for maintaining these dock levelers?

A: Regular inspection of the hydraulic system, checking the epoxy coating for damage, and ensuring all safety mechanisms like the emergency stop switch are functional will keep the dock levelers in optimal working condition.Q: How does this equipment support compatibility with forklifts and other loading tools?

A: The deck is designed to withstand significant loads and features a reinforced lip, ensuring compatibility with various forklifts and loading equipment for seamless transfer of goods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+